Prosystem

Usually responds within an hour

ProSystem excellence is not only to be found in in packaging machinery or proprietary technology. It is also in the services that we offer to customers, regardless from which industries. Our promise is to assist our customers every step of the way, with the same commitment for each project phase. And after the sale, our work continues.

Find out why ProSystem has become the reference point in packaging machinery solutions in Italy and Europe, and why companies from all over the world continue to choose us.

For every packaging machinery project, ProSystem offers a wide range of pre-sales services, which guarantee the optimization of available resources and an end-result that meets the needs of the customer’s packaging plants.

For every new request, ProSystem carries out an analysis to examine packaging machinery solutions and spaces already available on site. It also creates "tailor-made" proposals both for individual packaging machinery solutions as well as for complete packaging systems.

After the first phase of analysis, ProSystem creates a detailed project with possible packaging machinery solutions that will be installed or designed ad hoc directly by the ProSystem technical team. Finally, it will align the project proposal with the needs and budget available.

Once the machinery has been built and installed, ProSystem provides a range of services in order to guarantee the correct functionality of each packaging machinery solution thus ensuring durability and depreciation.

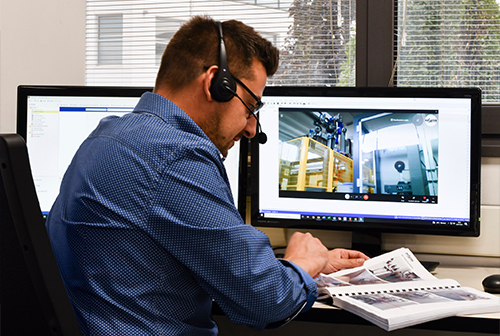

In addition to the construction and installation of single packaging solutions and complete packaging plants, ProSystem provides a comprehensive offering of training services for technical staff, preventive and ordinary maintenance services, technical and electronic assistance, safety and security updates ensuring the durability of the product. ProSystem, at any time, provides technical assistance, by telephone, via the Internet and directly on site, using its own specialized technicians, responding to every enquiry quickly and promptly.

In a dynamic environment like the current times, speed and flexibility are added values. ProSystem makes its design team available for the review of production lines to meet every new customer need (new formats, new production speed and other modifications).

![]()

ProSystem manages the mechanical phase internally to guarantee our customers perfect packaging technologies in their smallest component. Thanks to continuous investments and a state-of-the-art technology, the company’s mechanical department, manufactures high-precision components and rapidly replaces those that are worn out.

![]()

ProSystem Packaging can count on a team of mechatronic designers and technicians to create customized electrical systems. A fundamental aspect to provide the level of customization for which we are known: ProSystem’s Tailor-Made approach, with flawless design and engineering.

![]()

We want you to get maximum efficiency from our packaging machines. For this reason, before the assembly stage, customers are invited to our Verona offices to test the machinery and evaluate its performance directly before shipment at the customer’s location. (FAT - Factory Acceptance Test).

ProSystem has a large spare parts warehouse allowing it to carry out maintenance for its packaging solutions in 24-48 hours from the request, thus guaranteeing a quick recovery of the packaging lines.

![]()

We assist you with our packaging machinery solutions at every stage, even during installation, which is vital to ensure the perfect functioning of the product. ProSystem provides a team of qualified technicians for on-site assembly and start-up production. We will be by your side in optimizing your production, whatever your industry.

![]()

We want you to get maximum efficiency from our packaging machinery solutions. For this reason, during the assembly and start-up phase, we carry out a scrupulous test to verify the functionality of our systems, directly at your premises together with your staff. (SAT - Site Acceptance Test).

If you work in the world of packaging or want to learn more about our products and services, follow us on social networks. We will provide you with insightful information about our work through a unique story-telling style. Become part of our community.